Design

Over more than 25000 different bottles, jars and jerrycans designs have been produced with the patented production technology we use in our production process.

Next to the standard bottle design we can engineer bottles designs and in cooperate these solutions:

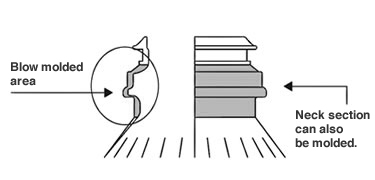

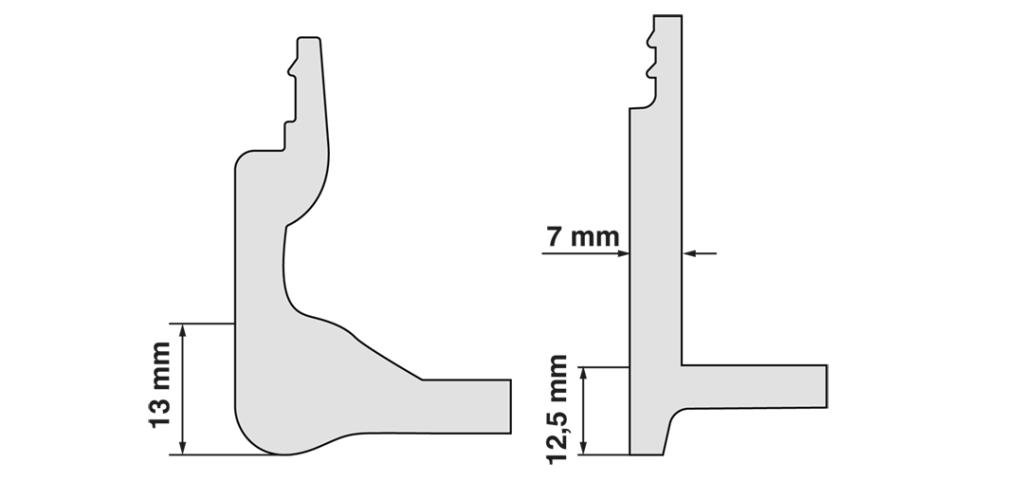

Neck light weighting

We can blow neck as well as body sections. This enables neck light weighting within a range that will not affect closure fit.

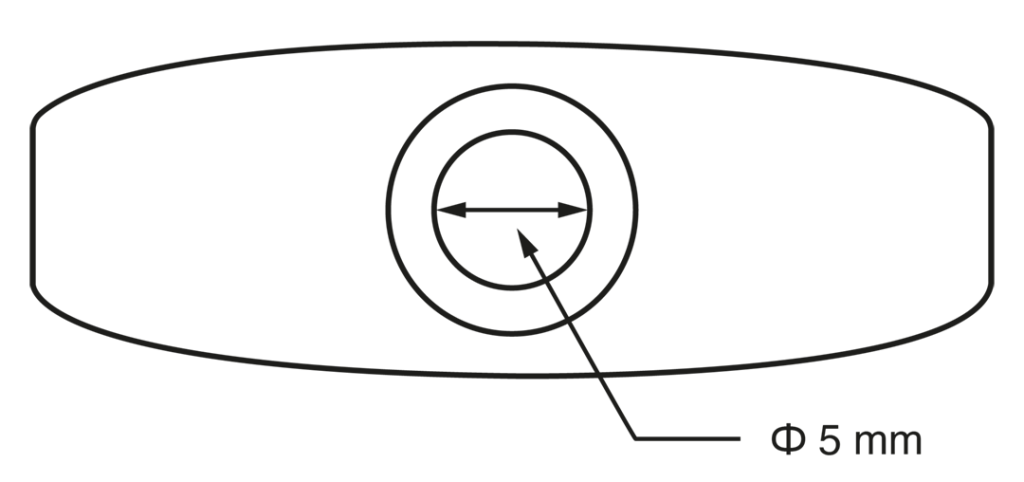

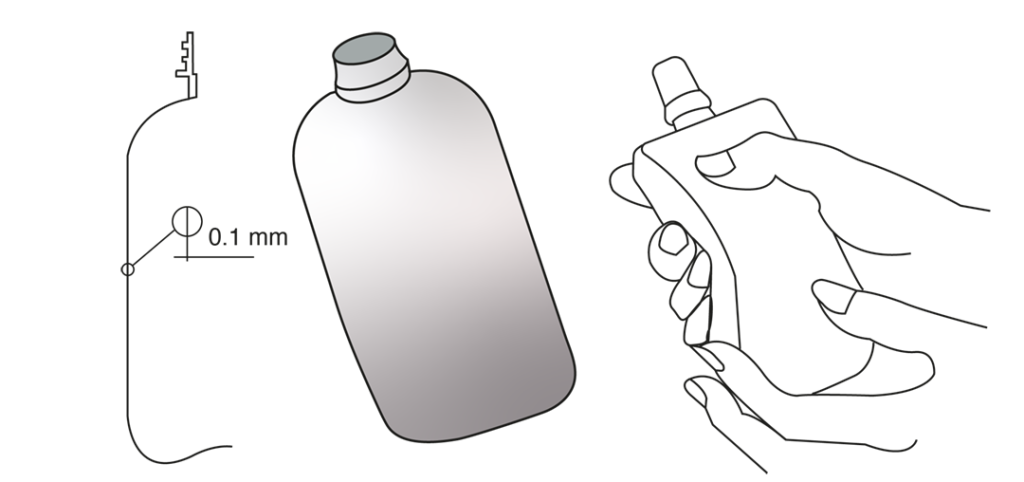

Ultra-narrow-necked container molding

This technology is used most often for eye drop bottles and other small containers. The minimum internal diameter can be about Φ5mm. This technology is suited to bottles with a capacity up to approximately 20mL.

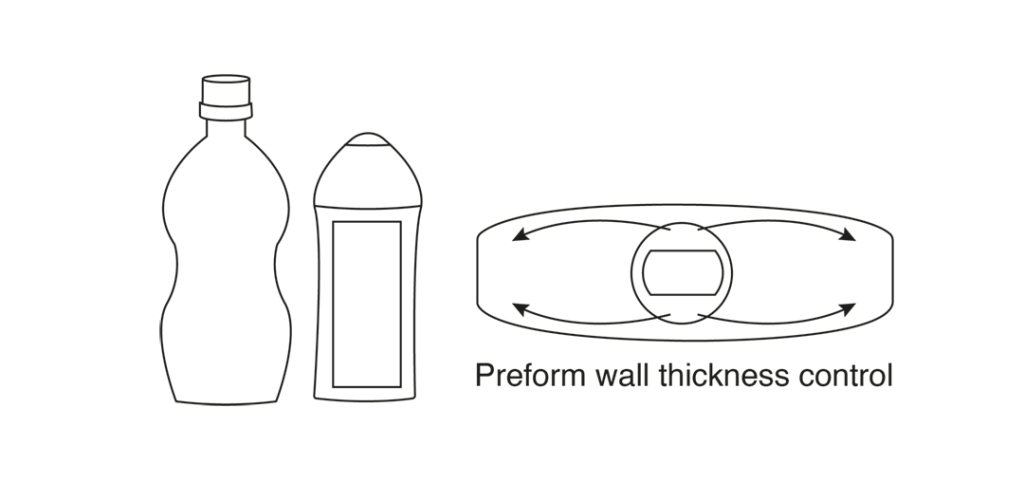

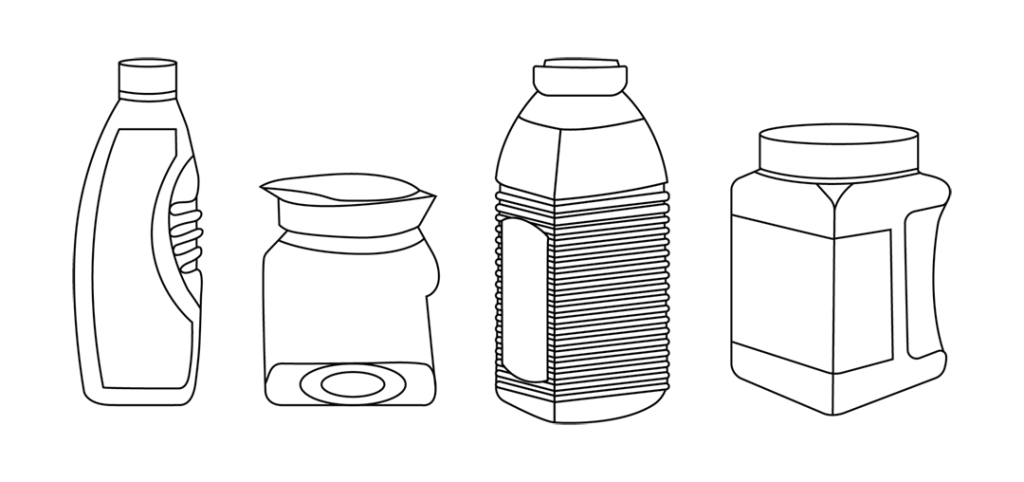

Oval container molding

Oval containers are in use in various applications including shampoo, hand soap, mayonnaise and detergent. They have the advantage of offering a wider label panel to the consumer, are easy to hold, and require less space when packed for shipping. With our new ovalizing technology, more heat is retained in the areas of the preform that require stretching, so adjusting wall thickness is much faster than before.

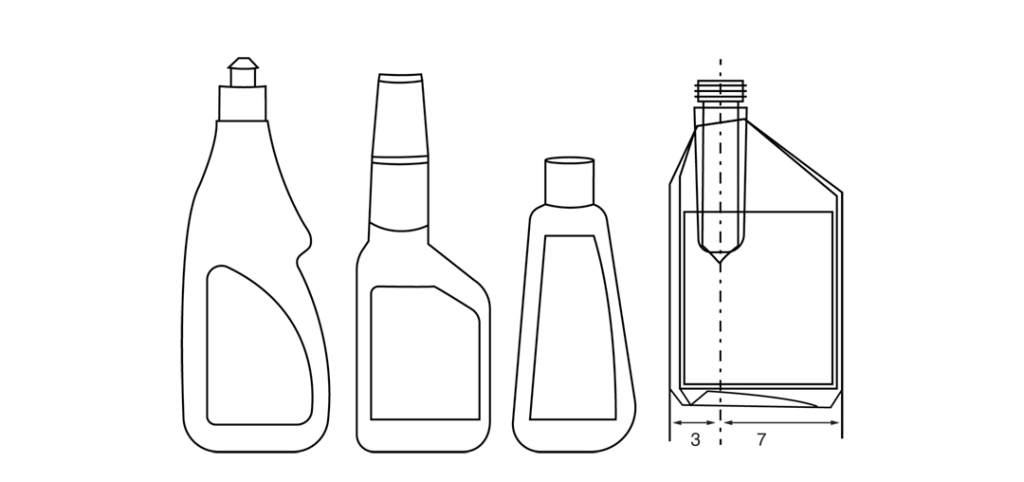

Off-center container molding

Off-center containers can be used for many different applications. Achieving a uniform wall thickness throughout an off-center product was quite difficult with previous molding methods, but is now possible with our technology. It also enables product light weighting and material cost reductions.

This type of bottle is being used for trigger sprays, spice jars, engine oil containers, juice bottles, and more recently for water bottles.

Small container molding

Small containers of approximately 5mL for pharmaceuticals, eye drops, samples, amenities and such like can be molded with greater precision than glass containers. This molding technology goes one step further as well and enables the molding of containers with an internal neck diameter of as little as 5mm, or variable wall-thickness preforms for container ovalizing, while at the same time accurately heat conditioning the preform for highly precise stretch blowing.

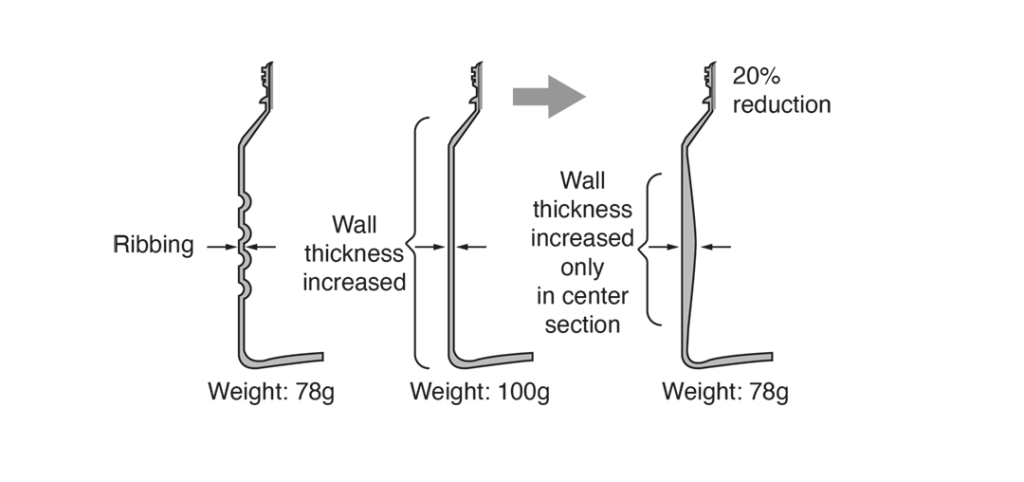

Wide mouth container vacuum control

Vacuum panels or ribs are generally not used on wide mouth containers. Even though increased wall thickness can prevent vacuum deformation, the increased container weight means increased material costs. Our production technology enables localization of thicker walls at the center of the container body, which prevents this deformation. This means weight savings.

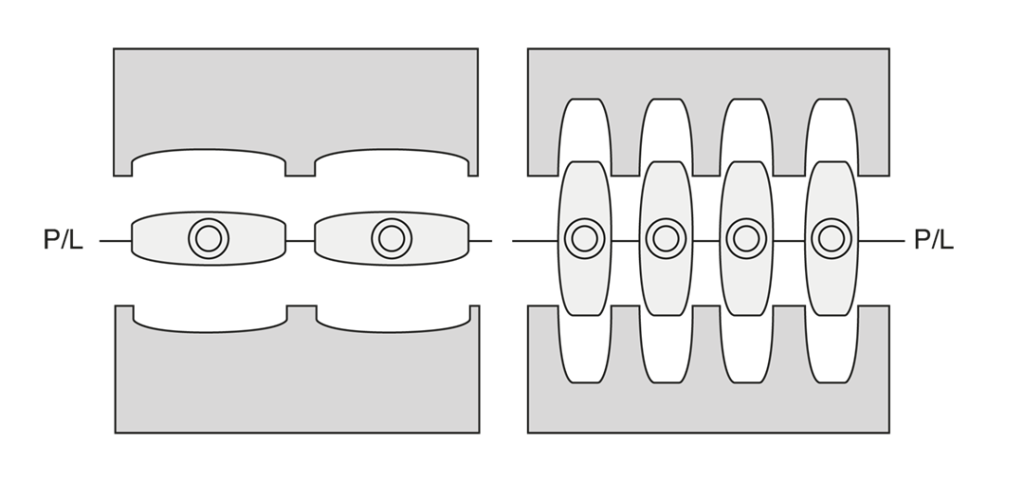

Inconspicuous parting line mold technologies

We enable molding that makes parting lines almost unnoticeable. This enables cavities to be increased by locating parting lines on the front panel, boosting production by 25-100%.

Stable molding of narrow-necked PP containers

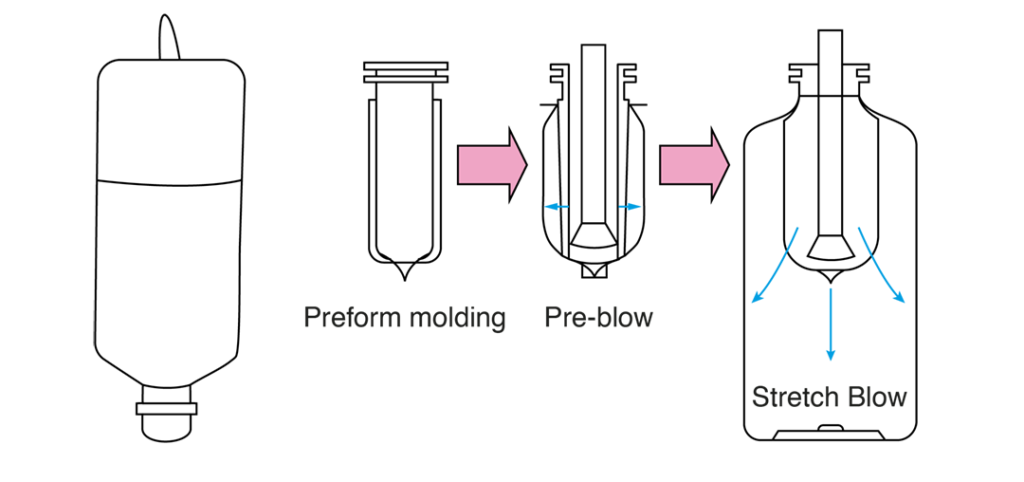

Polypropylene is a highly moisture resistant material. One common medical application that utilizes this characteristic is transfusion bottles.

Our pre-blow system is an original blow system that enables the preform temperature to be maintained with the stretch rods while the bottle is quickly blown, thus preventing any shrinkage from occurring. This enables the stable molding of high quality, high precision containers.

Thin-walled container molding

Thin-walled container molding is used widely for refill containers and containers designed to reduce refuse volume. Off-centering is prone to occur during the stretch-blow phase when molding ultra-thin oval containers, but our mold mechanism eliminates off-centering, enabling the molding of containers with walls of even thickness.

Thick-walled container molding

We have enabled the molding of ultra-thick-walled containers of a quality thought to be almost impossible up to now. The ability to mold thick-walled containers that feel like glass expands the potential for plastic containers. A single stage, 3-station mechanism enables the molding of thick-walled containers with less energy than other molding methods.

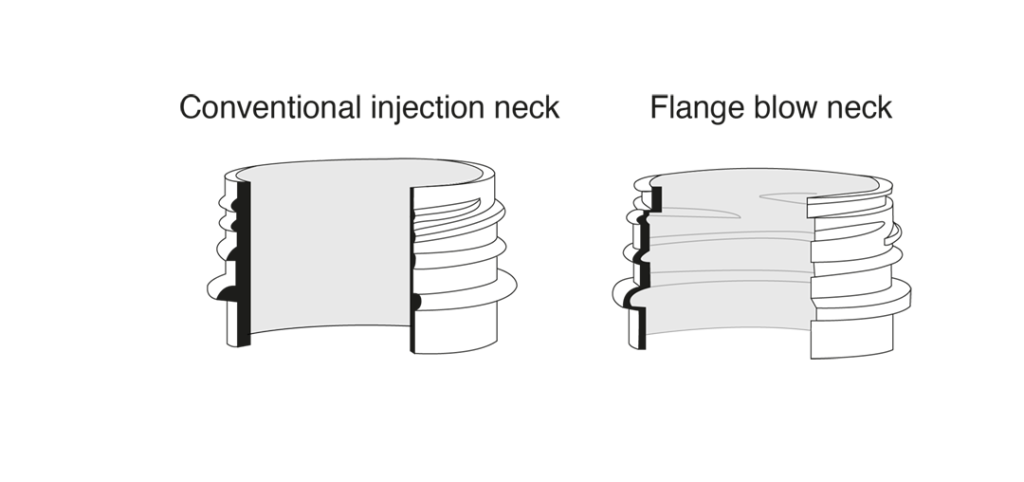

Flange blow neck molding

Flange blow molding eliminates the need for trimming and other secondary manufacturing processes, and can significantly reduce neck weight.

It is suited to the molding of medium and wide mouth necks. It is used for medium mouth oil and water containers, and for wide mouth containers for viscous contents or powders and other solids.

Drinking bottles

Functional design is a top priority of molding water bottles, including such aspects as cap orientation. We can leverage extensive experience to address your needs. Though it depends on the functions required of the water bottle, materials such as PP, Tritan and PET are suited to molding water bottles. PP, Tritan and other heat-resistant materials are ideal for water bottles that are washed with hot or boiling water.

Grip containers

These are used for seasonings, oil, foods and various other purposes. At rPET Direct, we can design appropriate grips after ascertaining customer wishes and considering container size.

High-pressure containers / PET cans

rPET Direct supports the molding of high-pressure containers. Pressure resistance of about 4vol is required by carbonated drink bottles. Appropriate selection of material is essential to the molding of high-pressure containers, and secondary manufacturing may also be necessary.

Handled containers

Even in cases requiring highly precise shaping of the section where the handle will be attached, our production technology enables stable molding of handled containers through wall thickness control.

Long neck bottles

Long necks of about 100mm including the threaded section can be molded. These can be used for long neck designs such as wine bottles, and can be given functions unique to long necks.